From Pasture to Masterpiece: Wool’s Journey in Moroccan Rugs

Follow wool’s journey from Atlas mountain sheep to hand-spun Moroccan rugs. Through cleaning, carding, and spinning, artisans craft textures machines can’t replicate.

What makes the wool in authentic Moroccan rugs feel so different from mass-produced alternatives? Long before the first knot is tied, a remarkable journey unfolds that transforms raw fleece into the foundation of these cultural treasures. This process—refined over centuries in Morocco's Atlas Mountains—combines deep ecological knowledge, community cooperation, and sustainable practices that modern manufacturing simply cannot replicate.

Understanding this journey helps explain why genuine handmade Moroccan rugs possess qualities that industrial production can never truly duplicate—a living connection to landscape, tradition, and human care that gives these textiles their extraordinary character and longevity.

The Living Source: Mountain Sheep of Morocco

The journey begins with the distinctive sheep breeds that have adapted to Morocco's varied landscapes over centuries. Unlike the standardized wool used in commercial production, Moroccan artisans work with wool that reflects the specific environment where the sheep lived—creating textiles with regional character and terroir similar to fine wines.

Regional Wool Character

Different regions produce wool with distinctive qualities that skilled artisans select for specific purposes:

High Atlas Wool: Sheep in these rugged mountain environments develop thick, lanolin-rich fleece that creates exceptionally durable rugs. The harsh climate and altitude contribute to wool with natural water-resistant properties and remarkable insulation value—qualities that translate directly into the finished textiles.

Middle Atlas Wool: This region's moderate climate produces wool with excellent elasticity and natural sheen. When properly processed, this wool creates rugs with a subtle luster that changes character as light moves across them throughout the day.

Eastern Region Wool: Sheep from Morocco's eastern territories produce wool known for its length and strength, ideal for the intricate knots required in certain traditional patterns. This wool allows for the crisp definition of geometric designs that maintain their clarity over decades of use.

Expert artisans don't simply use whatever wool is available—they carefully select specific types based on the intended characteristics of the finished rug. This selection process represents the first creative decision in a long chain of choices that will define the final piece.

The Harvest: Shearing with Respect

Unlike industrial wool production with its focus on maximum yield, traditional Moroccan wool harvesting follows rhythms developed through generations of careful observation and respect for the animals.

Shearing typically occurs in late spring, when temperatures have warmed but before summer heat intensifies. This timing ensures sheep aren't left vulnerable to cold while allowing their fleece to regrow before winter returns—one of many examples of traditional ecological knowledge embedded in this craft.

Hand shearing allows for careful assessment of different parts of the fleece. The finest wool from the shoulders and sides might be reserved for rugs, while coarser sections serve other purposes. This holistic approach minimizes waste while matching material qualities to appropriate uses.

The Transformation: From Raw Fleece to Workable Fiber

Once harvested, the raw wool undergoes a remarkable transformation through entirely manual processes that preserve its natural qualities while preparing it for artistic use:

The Cleaning Ritual

The first step involves meticulously cleaning the raw wool by hand to remove debris while preserving its essential character. Unlike industrial scouring that strips wool of its natural oils, traditional cleaning methods in Morocco's Atlas Mountains use techniques that maintain appropriate amounts of lanolin—the natural oil that gives authentic rugs their water-resistance and distinctive feel.

This cleaning often takes place in mountain streams or with collected rainwater, using natural soaps derived from plants like saponaria root. The water quality itself becomes part of the regional character of the wool, as mineral content affects how the fibers respond to subsequent processing and dyeing.

The Meditative Art of Carding

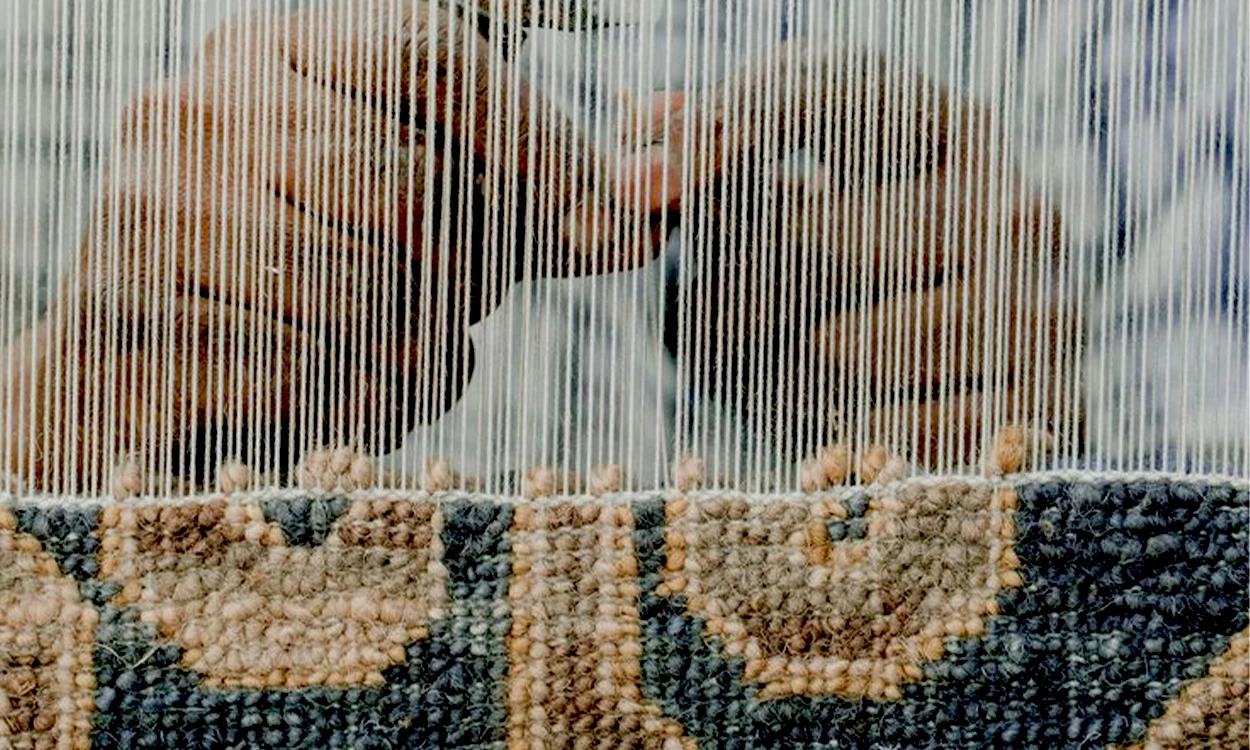

After cleaning, the wool undergoes carding—a process of repeatedly combing the fibers to align them in preparation for spinning. This labor-intensive work is often performed by elder members of the community, whose experienced hands can assess the wool's quality through touch.

Traditional hand cards feature fine metal teeth set in wooden paddles, tools that have remained largely unchanged for centuries. The carder develops a rhythm that efficiently separates and aligns fibers without breaking them, preserving the wool's natural length and strength.

This process isn't merely mechanical but involves continuous assessment and adjustment. The carder makes decisions about when wool requires additional passes or when certain sections should be set aside for different purposes based on subtle qualities that machines cannot detect.

The Walking Spinners: Yarn Creation in Motion

The transformation from fiber to yarn occurs through hand-spinning, traditionally using a wooden drop spindle. The spinner—almost always a woman—often walks while spinning, creating a rhythm that produces yarn with the perfect tension. This distinctive technique creates yarn with a character that mechanical spinning cannot replicate.

Spinners adjust their technique based on the intended use of the yarn. Warp threads—which form the foundation of the rug—must be spun with maximum strength and consistency. Weft and pile yarns might be spun more loosely to create specific textural effects in the finished piece.

It's during this spinning stage that the character of the future rug begins to emerge; the thickness, twist, and consistency of the yarn will influence everything from the feel of the finished piece to how it accepts dyes and how the knots will appear when completed.

Community Knowledge: The Invisible Foundation

What makes this wool preparation process remarkable isn't just the technical steps but the collective knowledge that guides them. This isn't knowledge found in books but wisdom transmitted through direct demonstration and practice across generations.

In many Atlas Mountain communities, wool preparation becomes a social activity where stories and songs accompany the work—a practice that serves both to make repetitive tasks more pleasant and to encode technical knowledge in memorable forms that can be easily transmitted to younger generations.

Women might assess wool quality through multiple senses—not just sight and touch but even sound, rubbing fibers between their fingers to hear the characteristic crisp sound that indicates proper cleaning and preparation. These assessment techniques represent sophisticated quality control methods developed without modern technology.

The Living Result: Wool with Character

The wool that emerges from this traditional preparation process possesses qualities that industrial processing cannot reproduce:

Natural Variation: Slight differences in thickness and texture create the characteristic visual depth that makes handmade rugs so visually compelling. Rather than the flat uniformity of machine-processed wool, traditionally prepared fibers create surfaces with subtle dimension that captures light in complex ways.

Retained Lanolin: By preserving some of the wool's natural oils, traditional processing creates fiber that remains naturally stain-resistant and water-repellent—qualities lost in the harsh chemical scouring of industrial wool production.

Structural Memory: Hand-processed wool retains its natural crimp and elasticity, allowing rugs to regain their shape after compression and contributing to their remarkable longevity.

Dye Receptivity: Traditional preparation creates wool that accepts natural dyes in ways that create the characteristic depth and variation of color seen in authentic Moroccan rugs. The subtly irregular surface of hand-processed wool allows dyes to penetrate differently throughout the fiber, creating the living color quality that changes under different light.

The Value of Process in a Fast-Paced World

In an era of instant gratification and industrial efficiency, the wool preparation methods of Moroccan rug makers might seem unnecessarily time-consuming. Yet the investment of time and care creates materials with qualities that simply cannot be replicated through faster means.

When you run your hand across an authentic Moroccan rug, what you're feeling is this entire journey—from mountain pastures to careful selection, from hand cleaning to walking spinners. You're experiencing the result of ecological knowledge, community cooperation, and artisanal excellence combined in ways refined over countless generations in the Atlas Mountains.

This connection to process, place, and tradition isn't merely romantic nostalgia but represents practical wisdom about creating textiles with extraordinary durability, character, and sustainable origins. In a world increasingly concerned with the environmental and human costs of mass production, these traditional methods offer valuable lessons about creating objects that truly stand the test of time.